SDS Nahco Dry Type Desulfurization

Technology Introduction

SDS sodium bicarbonate (baking soda) dry desulfurization is a proven 100% dry process widely used in flue gas desulfurization across industries globally. This technology injects ultra-fine sodium bicarbonate into the desulfurization reactor, where it fully mixes with flue gas and undergoes chemical reactions to remove SO₂. It achieves ≥90% desulfurization efficiency, eliminates wastewater and white smoke issues, and features a simple, highly automated design.

Working Principle

The principle of SDS sodium bicarbonate dry desulfurization is as follows: After flue gas enters the desulfurization reactor, fine sodium bicarbonate powder is injected simultaneously. Activated by the high temperature of the flue gas (aided by additives), sodium bicarbonate expands in volume and decomposes into sodium carbonate with high reactivity and adsorption capacity.

Sodium carbonate mixes thoroughly with flue gas, reacting with acidic gases (SO₂, SO₃, HCl, etc.) to form sodium sulfate and other sodium salts, removing most sulfur from the flue gas. Additionally, sodium-based desulfurizing agents continue to react with residual sulfur dioxide in the flue duct and dust collector, ensuring thorough purification.

Reaction Equations

Primary Reaction:2NaHCO₃ = Na₂CO₃ + CO₂ + H₂O (flue gas temperature ≥150°C)

Na₂CO₃ + SO₂ + 1/2O₂ = Na₂SO₄ + CO₂

Side Reactions:Na₂CO₃ + SO₃ = Na₂SO₄ + CO₂

2HCl + Na₂CO₃ = 2NaCl + CO₂ + H₂O

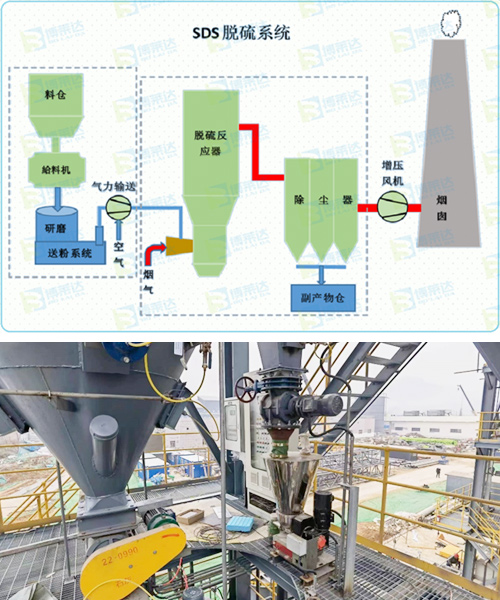

Process Flow

The SDS sodium bicarbonate dry desulfurization process follows these steps: First, ground sodium bicarbonate desulfurizing agent is temporarily stored in a silo. Next, a variable-speed feeder at the bottom of the silo (adjusted based on flue gas volume) delivers the appropriate amount of sodium-based agent. The agent is then blown into the desulfurization reactor via a powder conveyor fan, where it mixes at high velocity with incoming flue gas to react and remove acidic components.

Process Features

Key features of the SDS sodium bicarbonate dry desulfurization process:

1.A buffer silo below the grinder automatically adjusts agent dosage via an electric feed valve based on operational conditions.

2.The silo is equipped with level gauges to trigger automatic refills as the agent level changes.

3.Fluidization devices in the silo prevent agent bridging and caking due to moisture.

Critical technical parameters:

1.Sufficient contact time between agent and flue gas (minimum 1.5 seconds).

2.Ultra-fine agent particle size (preferably<35μm, D90).

3.Moderate sulfur content in flue gas (typically ≤500mg/m³).

4.Adequate reaction temperature (≥150°C; optimal range: 150~250°C).

Technical Advantages

01

Desulfurization efficiency up to 95%+, ensuring long-term compliance.

02

Compact footprint and flexible layout, adaptable to space constraints.

03

Minimal temperature drop (only ~10°C), high exhaust temperature, and no white smoke issues.

04

100% dry operation eliminates wastewater treatment and secondary pollution.

05

High agent utilization; byproducts are recyclable (e.g., as cement additives or raw materials for tailings solidification).

06

Simple system design with low power consumption, low failure rates, and long service life.

07

Easy operation and maintenance, with flexible adjustment, strong controllability, and high automation.

08

Paired with high-efficiency dust removal, achieving ≤10mg/Nm³ particulate emissions—close to ultra-low standards.

Application Fields

SDS sodium bicarbonate dry desulfurization is ideal for tail gas treatment in gas-fired boilers, biomass boilers, incinerators, smelting furnaces, coking ovens, ceramic kilns, and other industrial furnaces—particularly for businesses concerned about white smoke.

Gas fired boiler

A furnace for smelting metal