Industry Solutions & Case StudiesFrom crisis to compliance, how we solved real-world crises?

-

Spray Tower Flue Gas De-whitening Project

A company in Chongqing has a spray tower. During the low temperatures in winter, the white smoke em...

Read More

-

New Material Company's Hazardous Solid Waste Incineration Flue Gas De-whitening Project

A new material company in Jiangsu faced complaints from residents due to the visible smoke and long ...

Read More

-

China's Hazardous Waste Incineration Flue Gas Treatment and Odor Removal Project

A hazardous waste incineration company in Zhejiang faced the problem of high-concentration smoke and...

Read More

-

Innovative De-whitening of Calcination Kiln Flue Gas in China's Chemical Industry

A chemical enterprise in Henan has calcination kilns. During the production process, the dust conten...

Read More

-

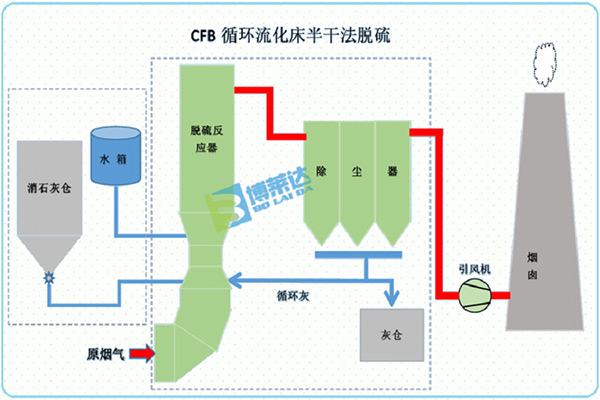

Emission Reduction Boiler Flue Gas Treatment for a Chinese Company

An enterprise in Inner Mongolia operates two 40T/H chain grate boilers fueled by coal. However, the ...

Read More

-

Sulfuric Acid Desulfurization and De-Whitening Project of a Chemical Enterprise Achieves Significant Emission Reduction

Project category:Sulfuric acid production desulfurization flue gas de-whitening project Products/tec...

Read More