Bolaida's Condensation Phase-Change Dehumidifier eliminates white smoke from industrial stacks while recovering water and heat. Custom-engineered for >99% dehumidification efficiency, it meets stringent environmental standards with low OPEX and zero chemical additives. Ideal for boilers, kilns, and incinerators.

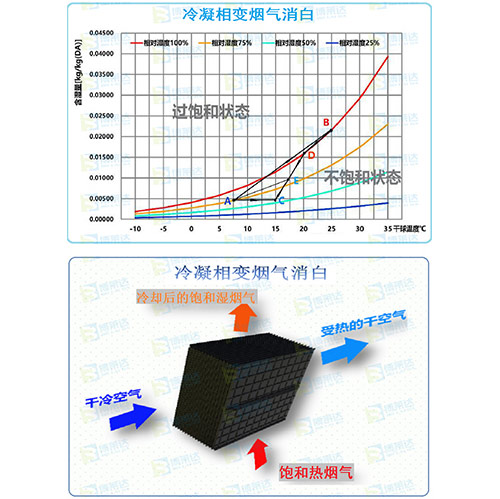

Flue gas exchanges heat with ambient air via plate heat exchangers. Moisture condenses for collection, while preheated air mixes with dried gas to lower dew point and eliminate white smoke. Removes sulfates, aerosols, and fine particles.

Eliminates white smoke from chimneys while enabling waste heat recovery and condensate recycling, reducing overall emissions.

Simple maintenance with no additional labor required—only minimal power consumption for supporting fans.

Core components made of polymer composite materials, resistant to acids/alkalis, ensuring long service life.

Flat-panel structure with smooth surfaces minimizes flow resistance.

Modular construction for easy assembly, high space efficiency, and virtually no wearable parts.

Integrated manufacturing and installation typically completed within 60 days.

| Parameter | Type A | Type B |

| Operating Temp | 40-80°C | 90-150°C |

| Materials | Graphene, Stainless Steel | Same as Type A |

| Airflow | Aluminum Composite≥20,000 Nm³/h (operational conditions) | Customizable |

| Dimensions | Custom-built to requirements | Custom-built to requirements |

| Indicator | Value | Notes |

| Dehumidification Efficiency | >99% | No visible plume at 0°C |

| Pressure Drop | <500 Pa | Plate heat exchanger design |

| Water Recovery | ≥90% | Reusable in processes |

| Humidity Tolerance | ≤20% (inlet) | Moisture content |

Requirement Analysis

Data Collection

Solution Design

Manufacturing

Installation

Lifetime Support

Suitable for flue gas dewhiting and acid mist removal in boilers, kilns, incinerators, and smelting processes across multiple scenarios including desulfurization, drying, slag flushing, and incineration.