Bolaida's Ion Beam White Smoke Eliminator redefines flue gas treatment through condensation-phase physics and non-thermal plasma technology. Engineered for extreme climates from Dubai's deserts to Nordic winters, this system eliminates visible plumes at 0°C while capturing aerosols, oil mists, and acid vapors in a single-tower design. With >98% dehumidification efficiency and 70% lower energy consumption than electric precipitators, it delivers compliance without compromising operational economics.

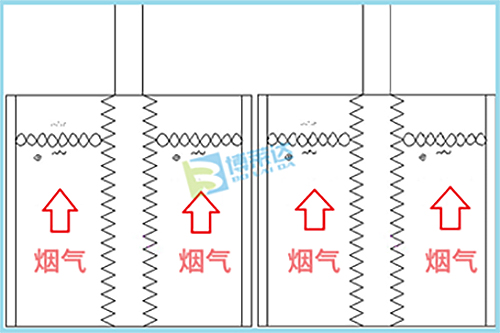

Flue gas exchanges heat with pre-cooled air in titanium alloy plate heat exchangers, condensing and recovering ≥90% of moisture.

A 20kV high-voltage ion field fragments aerosols, oil mist, PM2.5, sulfuric acid mist, and tar into collectible particles.

Dehydrated flue gas mixes with preheated air, reducing relative humidity to<30%. The mixed gas exits the stack at temperatures far above the dew point, preventing moisture condensation and visible plumes.

≥98%, Zero visible emissions at 0°C.

Meets Grade 2 energy standards, consuming only fan power.

Captures fine particulates and pollutants during condensation.

Collects and reuses condensate from dehumidification.

Eliminates visible plumes at -10°C, resolving neighborhood disputes.

Removes PM2.5, sulfates, and oil aerosols to meet strict emission standards.

Retrofit completed within 60 days without halting operations.

01

98% removal rate in extreme cold/rainy conditions.

02

Centralized monitoring system + mobile app for remote control.

03

Operating costs reduced by 66% compared to electric mist eliminators.

04

Simultaneously eliminates aerosols, particulates, acid mist, and tar.

05

Customizable materials (titanium, stainless steel 304/316/2205) for harsh environments.

06

Modular design enables 50% faster installation and flexible layout.

| Model | LZTB200-L |

| Operating Temperature | ≤50°C |

| Power Consumption | ≈2 kWh per 10,000 Nm³/h airflow |

| Airflow Capacity | 20,000–1,000,000 Nm³/h (customizable) |

| Materials | Titanium alloy, stainless steel (304/316/2205) |

| Customization | Size and layout tailored to project requirements |

Widely used in boilers, kilns, drying systems, incinerators, smelters, textiles, chemicals, and food processing industries, including:

- Desulfurization Flue Gas: Phosphate chemicals, titanium dioxide, lithium battery production, glass, fertilizers.

- Industrial Furnaces: Coke ovens, smelters, incinerators, roasters, calciners, oxygen-enriched furnaces.

- Key Processes: Boiler plume control, spray tower emissions, waste incineration (hazardous/solid), drying exhaust.