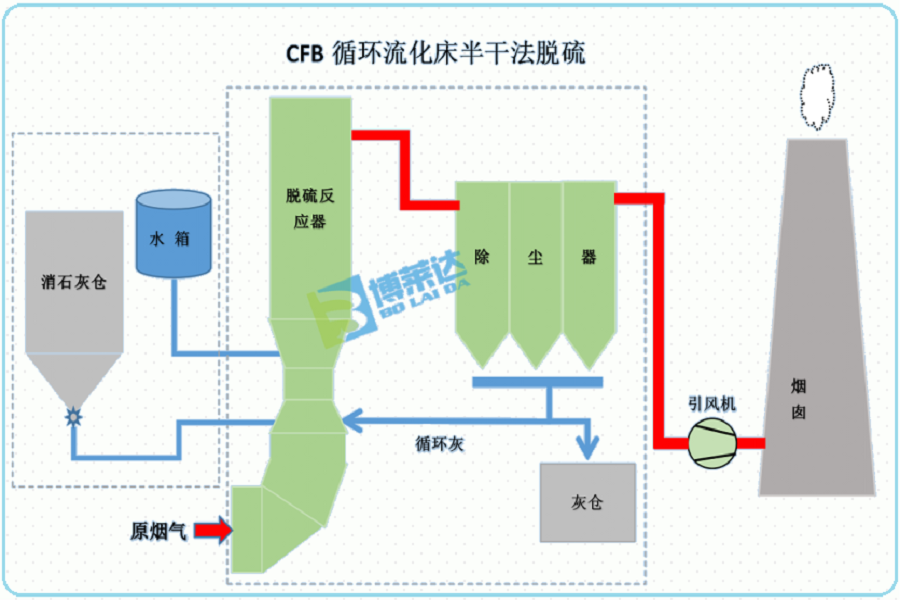

Bolaida's FRP CFB Desulfurization Tower utilizes semi-dry flue gas desulfurization (FGD) technology based on a circulating fluidized bed (CFB) system. With 10+ years of engineering expertise, our towers are custom-designed for diverse industrial needs, offering high corrosion resistance, zero scaling, and clog-free operation. Proven in 100+ SOx removal applications

The CFB semi-dry FGD process uses calcium-based sorbents to neutralize SO₂/SO₃ in flue gas. Activated by humidification, the sorbent circulates in the tower, ensuring 95%+ desulfurization efficiency at a low Ca/S ratio (1.1-1.3). This method also removes HF/HCl and generates dry, recyclable byproducts.

Cost-Effective: 50-70% lower CAPEX/OPEX vs. wet FGD.

Zero Wastewater: No liquid discharge or visible plumes.

Automated Control: Adapts to varying sulfur loads.

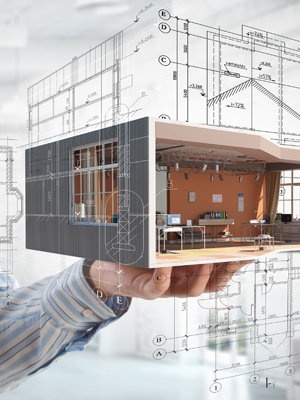

Tailored solutions for your plant layout.

Lightweight, durable, and corrosion-resistant.

Eliminates spray nozzle blockages.

❌ Poor SOx removal

✅ Guaranteed Efficiency

❌ Frequent leaks

✅ Leak-Free

❌ High maintenance

✅ Low OPEX

Design, customization, installation.

Rapid prototyping with 3D simulation.

FRP outperforms steel in harsh environments.

10-year expertise ensures optimal performance.

01

Dynamic simulations and on-site trials ensure leak-free operation.

02

From material selection to final inspection.

| Parameter | Details |

| Efficiency | ≥95% SOx Removal |

| Material | FRP/PP/Stainless Steel/Carbon Steel |

| Customization | Size, color, and layout supported |

| Application | Coal-fired boilers, kilns, sintering machines |

FRP composite resists UV, moisture, and chemical erosion.

Adapted to your site constraints and emission limits.

Clog-free, low energy use, and easy installation.

The CFB (Circulating Fluidized Bed) semi-dry desulfurization process is suitable for flue gas desulfurization in coal-fired power boilers, cogeneration boilers, central heating boilers, sintering machines, pellet furnaces, coking furnaces, glass furnaces, ceramic kilns, etc.