Bolaida's Baghouse Dust Collector delivers >99.9% efficiencyin capturing dry particulates. Engineered with smart pulse-jet cleaningand advanced filter media, it meets ultra-low emission requirements for various dry dust working conditions, the Bag House Dust Collector excels in scenarios like coal-fired boilers, ore crushing, biomass combustion, and cement kiln tails, providing clean air solutions for industrial production.

The CFB semi-dry FGD process uses calcium-based sorbents to neutralize SO₂/SO₃ in flue gas. Activated by humidification, the sorbent circulates in the tower, ensuring 95%+ desulfurization efficiency at a low Ca/S ratio (1.1-1.3). This method also removes HF/HCl and generates dry, recyclable byproducts.

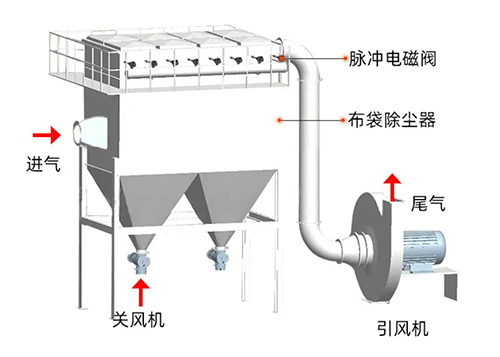

When resistance hits 1500-2000Pa → Pulse valves activate → Reverse air jet cleans bags → Dust cake falls into hopper.

Dust removal efficiency ≥99.9%, with 99% capture rate for PM2.5

Stable emission concentration ≤10mg/m³, meeting stringent ultra-low emission standards

Temperature resistance: Standard media ≤260°C, PTFE media withstands 300°C

Dust compatibility: Optimized for dry, non-sticky dust (fly ash/cement/metal oxides)

Load fluctuation: Handles 30%-120% load variation, 100% boiler startup/shutdown synchronization

Filter life: Premium PPS bags last ≥24 months, 30% lower replacement cost

Energy saving: Pulse valves consume only 0.3-0.5kWh per 1,000m³ flue gas

Smart monitoring: Differential pressure sensors + PLC ensure ≥95% fault accuracy

Compact footprint: 40% smaller than ESPs, ideal for retrofit projects

Rapid installation: Standardized modules cut assembly time by 50%, no production halt

Corrosion protection: Polyurea-coated carbon steel / stainless steel options, ≥10-year acid/alkali resistance

| Industry | Application | Dust Type | Emission |

| Power | Coal/Biomass Boilers | Fly Ash/Straw | ≤10mg/m³ |

| Cement | Kiln Exhaust | Cement/Gypsum | ≤15mg/m³ |

| Steel | Blast Furnace | Iron Oxide | ≤20mg/m³ |

| Chemical | Resin Drying | Polymer/Carbon Black | ≤5mg/m³ |

| Waste | Incineration | Fly Ash/Dioxins | GB 18485-2020 |

High Temp (>300°C): Ceramic fiber bags for glass/refractory kilns

Explosion-Proof: Anti-static bags + spark traps for Al/Mg dust

Food/Pharma: PTFE membrane bags for GMP compliance

| Parameter | Specification |

| Airflow | 5,000-1,000,000 m³/h (Customizable) |

| Filtration Velocity | 0.8-1.2m/min(Conventional dust)/0.6-0.9m/min(fine dust) |

| Pressure Drop | 1200-1800Pa(Stable operating state) |

| Filter Material | Polyester/PPS/PTFE/Glass Fiber |

| Cleaning | Pulse-Jet (Online/Offline) |

| Control Mode | PLC fully automatic control + remote monitoring |

| Lifespan | Structure≥20yr, Components≥10yr |

01

Media selection based on dust properties

02

Manufacturing to compliance testing

03

On-site service within 48 hours in China